Making Of

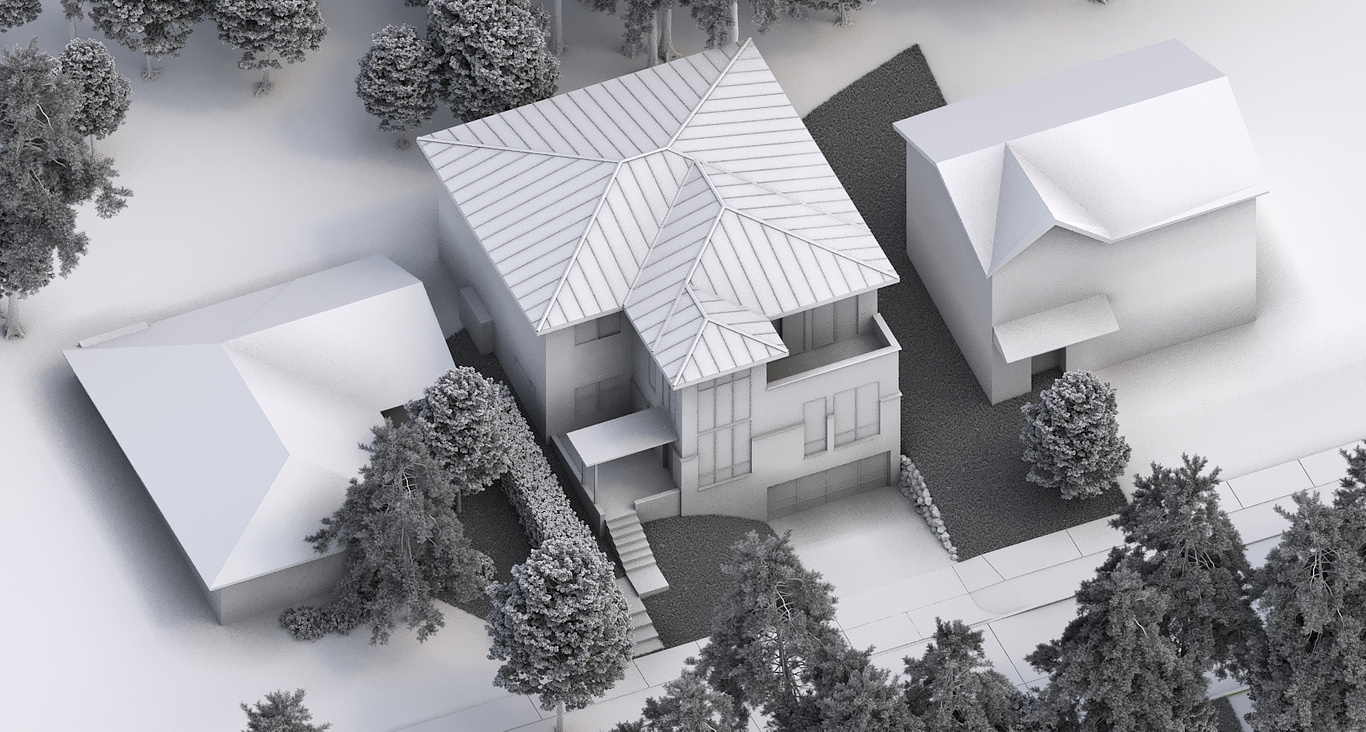

House in Laurelhurst, Seattle WA

The author of the refurbishment project is the architect Seth Hale, MAS Architecture LLC. The house is located in an ever-growing city Seattle, Washington. The changes made are significant - the second floor has been added, additional finishing materials, a new color of the roof and bricks have been introduced.

Initial data

Modeling

A simple scene with trees, bushes, and stones from the collections

Evermotion and R&D Group.

The greens are automatically planted by the Forest Pack plugin. Some elements were planted manually, previously converted to proxy files to avoid overload of the scene with extra geometry.

Evermotion and R&D Group.

The greens are automatically planted by the Forest Pack plugin. Some elements were planted manually, previously converted to proxy files to avoid overload of the scene with extra geometry.

Walls

The geometry of the walls consists of separate boxes enclosing one polygonal mesh, this modeling method is ideal for adjusting facades in the future.

Usually, the model consists of several grids belonging to different finishing materials.

For example, Brickwork is one object with its subobjects - boxes, siding - another object, plaster third, and so on.

Usually, the model consists of several grids belonging to different finishing materials.

For example, Brickwork is one object with its subobjects - boxes, siding - another object, plaster third, and so on.

Windows

In this project, double-glazed windows have already been installed.

In life, the window consists of two materials: outer - dark aluminum and inner - light. To quickly create such an effect, different IDs were assigned to the corresponding parts of the profile spline, and then the Multi / Sub-Object material with two materials was assigned to the finished window.

In life, the window consists of two materials: outer - dark aluminum and inner - light. To quickly create such an effect, different IDs were assigned to the corresponding parts of the profile spline, and then the Multi / Sub-Object material with two materials was assigned to the finished window.

Roof

The roof begins with a blank.

By the blank, we mean exactly the geometry of the roof constructed from the plane. Then, we use upper edges to create ridge cups, lower ones - we use

for eave modeling.

To simulate the Seam roof material, we use a profile of the appropriate shape, extruded by an extruding tool, trimmed with the slice modifier, and set at the right angle to its place. The method may seem not the best and perhaps outdated, but for us, this option is the most suitable.

By the blank, we mean exactly the geometry of the roof constructed from the plane. Then, we use upper edges to create ridge cups, lower ones - we use

for eave modeling.

To simulate the Seam roof material, we use a profile of the appropriate shape, extruded by an extruding tool, trimmed with the slice modifier, and set at the right angle to its place. The method may seem not the best and perhaps outdated, but for us, this option is the most suitable.

Materials

Download textures

For the client, it was critical to show the siding material as close to reality as possible.

Download textures

For the client, it was critical to show the siding material as close to reality as possible.

Final Images

How it looks now

thank you for your attention!

You must be logged in to post a comment. Login here.

About this article

House redesign in Laurelhurst. Working process with an Architect.

visibility111

favorite_border0

mode_comment0